Our rotary drum dryer is a crucial piece of equipment used across various industries, including cement, mining, construction, chemical, food, and fertilizer manufacturing.

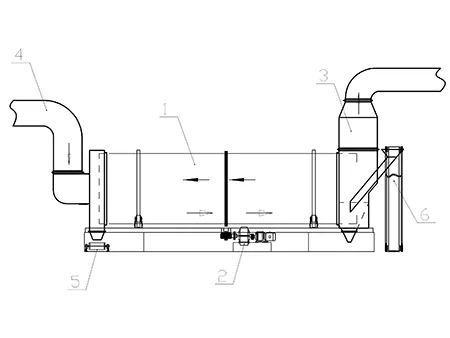

The rotary drum dryer consists of a cylindrical drum, internal lifter flights, a transmission device, support devices, and a sealed cover. It also has a feeding inlet and a discharge outlet equipped with thermocouples, which provide a clear display of the temperature changes at both ends of the dryer.

| Drum Size (m) | Production Capacity (t/h) | Power (kW) | Motor Model | Reducer Model | Ratio | Weight (t) |

| Ø1×10m | 0.5-1 | 5.5 | Y132M2-6 | ZL400- Ⅱ | 25 | 10.5 |

| Ø1.2×10m | 1-2 | 7.5 | Y160M-6 | ZL500-I | 25 | 13.5 |

| Ø1.5×12m | 2-5 | 11 | Y160L-6 | JZQ500-Ⅲ | 25 | 18.9 |

| Ø1.5×15m | 4-6 | 15 | Y180L-6 | JZQ500-Ⅲ | 25 | 21 |

| Ø1.8×12m | 5-8 | 18.5 | Y200L1-6 | ZQ50-16Ⅱ | 16.46 | 22.83 |

| Ø2.2×12m | 6-10 | 18.5 | Y200L1-6 | JZQ650-Ⅲ | 31.5 | 37.6 |

| Ø2.2×14m | 7-12 | 18.5 | Y200L1-6 | JZQ650-Ⅲ | 31.5 | 40 |

| Ø2.2×16m | 9-14 | 30 | Y225M-6 | JZQ750-Ⅲ | 31.5 | 45 |

| Ø2.4×14m | 10-16 | 30 | Y250M-6 | JZQ750-Ⅲ | 31.5 | 51 |

| Ø2.4×18m | 12-18 | 37 | Y250M-6 | ZL85-13-I | 27.16 | 54 |

| Ø2.4×20m | 14-22 | 37 | Y250N-6 | ZL85-13-I | 27.16 | 54.14 |

| Ø3×20m | 16-25 | 55 | Y250M-4 | ZL100-16-I | 41.52 | 78 |

| Ø3×25m | 32-36 | 75 | YR280M-4 | ZL100-16-I | 41.52 | 104.9 |

The drum is made of Q235 steel, and the internal liners can be customized to stainless steel.

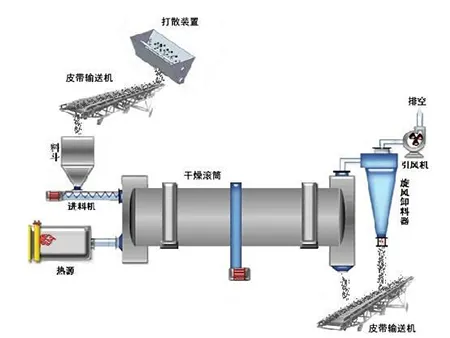

The heat source for the rotary drum dryer comes from a combustion unit. The dryer uses a counter-current heating mode, where hot air enters the dryer from the discharge end. The material to be dried enters the inclined rotating drum from the feed box and is pushed to the back by a screw lifter. As the drum rotates, the material tumbles and is repeatedly scooped up and dropped by the lifter flights. This allows for thorough heat exchange with the hot air, gradually drying the moisture from the material.

Our experts are on hand to help you with any questions you may have about fertilizer equipment.

The various raw materials of fertilizers go through the entire process of feeding, crushing, mixing, conveying, granulation, drying, cooling, screening, coating, and packaging.

Standard settings are approximately 600℃ at the inlet and 80-120℃ at the outlet.

We use a combination of stepped/helical lifter flights and a high-frequency vibrating device to prevent material from sticking to the drum walls.