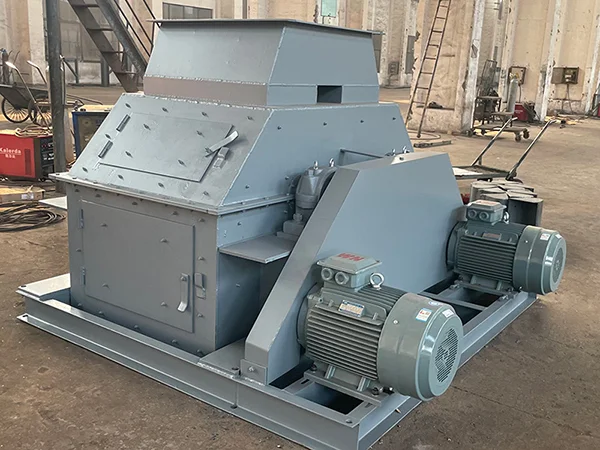

Chain mill crusher stands out for its unique chain design, offering superior anti-adhesion capabilities when processing high-moisture materials. This design effectively prevents clumping and blockages during the crushing process, making it particularly well-suited for fertilizers. With core components limited to a rotor, chains, and liner plates, and no complex gears or transmission systems, its assembly, disassembly, and daily maintenance are exceptionally convenient. This translates to minimal downtime and significantly lower operational costs.

Efficiently reduces material size while maintaining energy efficiency.

Optimizes space utilization in your facility.

Although chains are wear parts and require periodic replacement, the process is quick, and spare part costs are low, ensuring rapid return to production.

| Model | | | | | | |

| Rotation Diameter (mm) | Ø620 | Ø720 | ||||

| Center Distance (mm) | 500 | 600 | 700 | 800 | 1000 | 1200 |

| Rotation Speed (r/min) | 1440 | 1200 | ||||

| Power (kW) (Dual Motor) | 11×2 | 15×2 | 18.5×2 | 22×2 | 37×2 | 45×2 |

| Input Size (mm) | ≤50 | ≤80 | ≤120 | |||

| Final Size (mm) | ≈1 | |||||

| Production Capacity (t/h) | 5-8 | 10-15 | 15-20 | 20-25 | 25-30 | 30-40 |

Crusher shell material is customizable, Q235 steel is used as standard, with options for stainless steel upon client request. Chains are made from 20Mn for durability.

Our experts are on hand to help you with any questions you may have about fertilizer equipment.

The various raw materials of fertilizers go through the entire process of feeding, crushing, mixing, conveying, granulation, drying, cooling, screening, coating, and packaging.

This chain mill crusher is ideally suited for raw materials with high initial moisture content. It effectively handles sticky materials with moisture content ≤ 14%, such as compound fertilizers containing phosphorus and potassium. It's also suitable for materials with 6% free acid stickiness, like phosphate fertilizers. Expect a final product where 70% to 90% of particles are ≤ 1mm.

The cage mill crusher is an excellent choice for crushing limestone. It features multiple layers of concentrically arranged steel cage bars. Material is repeatedly impacted and crushed through friction as it moves between these high-speed rotating bars. This makes it ideal for medium to low-hardness, brittle materials, producing a uniform particle size with minimal over-grinding.

Our lump breaker is perfectly suited for this. It features high wear-resistant alloy components and a heavy-duty welded frame, paired with hydraulic overload protection for superior impact resistance and anti-deformation. Its vibration-damping design reduces loss from vibration, ensuring stability and long life even in harsh working conditions. This crushing machine is highly tolerant of incoming material, capable of directly handling large blocks of 1-1.5 meters without pre-crushing, meeting the demands of large-scale production.