Lump breaker is engineered to handle the toughest size-reduction challenges. It uses high-pressure impact, squeezing, and shearing forces to break down large materials into smaller particles, making them easier to process or transport. Built with high-wear alloy components and a heavy-duty welded frame, it features hydraulic overload protection for superior impact resistance and anti-deformation. The inclusion of shock-absorbing elements, like rubber buffers and rotor counterweights, reduces vibration loss, ensuring stability and a long operational life, even in harsh conditions. This size reduction machine is designed to be highly tolerant of incoming materials, capable of directly processing large blocks of 1-1.5 meters without pre-crushing. With automatic lubrication and quick-change wear parts, it supports continuous, all-day operation for large-scale production.

The lump breaker is specifically designed to tackle the problem of crushing large materials. It plays a critical role in pre-processing materials for subsequent crushing stages in industries like mining, construction, and metallurgy. Its core function is to use immense force to break down large chunks into a manageable size.

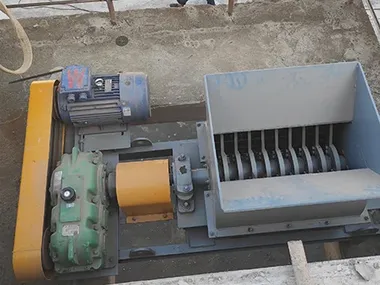

Urea after crushing by the lump breaker

| Model | Rotation Diameter (mm) | Input Size (mm) | Final Size (mm) | Production Capacity (t/h) | Motor Power (kW) | Reducer Model |

| | Ø600 | ≤100 | ≤50 | 5-8 | 5.5 | ZQ350 |

| | ≤150 | 10-15 | 7.5 | ZQ400 | ||

| | 15-20 | 11 |

Our experts are on hand to help you with any questions you may have about fertilizer equipment.

The various raw materials of fertilizers go through the entire process of feeding, crushing, mixing, conveying, granulation, drying, cooling, screening, coating, and packaging.

The lump breaker is the best choice when dealing with lumped or large-volume materials.

The cage mill crusher is an excellent choice for crushing limestone. It features multiple layers of concentrically arranged steel cage bars. Material is repeatedly impacted and crushed through friction as it moves between these high-speed rotating bars. This makes it ideal for medium to low-hardness, brittle materials, producing a uniform particle size with minimal over-grinding.

Our lump breaker is perfectly suited for this. It features high wear-resistant alloy components and a heavy-duty welded frame, paired with hydraulic overload protection for superior impact resistance and anti-deformation. Its vibration-damping design reduces loss from vibration, ensuring stability and long life even in harsh working conditions. This crushing machine is highly tolerant of incoming material, capable of directly handling large blocks of 1-1.5 meters without pre-crushing, meeting the demands of large-scale production.