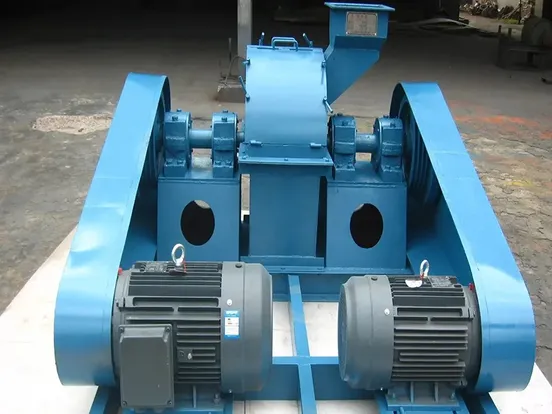

Cage mill crusher works by using multiple layers of concentric steel cages or crushing rings. As materials enter the crushing machine, they are repeatedly impacted and pulverized by friction between the high-speed rotating cages. This design is highly effective for materials of medium to low hardness.

Ideal for medium to fine crushing of materials like coal, gypsum, fertilizer, and limestone.

Produces a consistent, uniform particle size with minimal over-grinding, making it perfect for brittle materials.

The straightforward structure makes maintenance easy, but the cage bars are wear parts and need regular replacement.

The cage mill crusher is well-suited for crushing materials with a higher moisture content.

| Model | | | | | |

| Rotation Diameter (mm) | Ø600 | Ø800 | Ø1000 | Ø1300 | Ø1600 |

| Input Moisture Content (%) | ≤5 | ||||

| Input Size (mm) | ≤10 | ≤20 | ≤30 | ||

| Final Size (mm) | ≈0.5 | ||||

| Production Capacity (t/h) | 3-5 | 5-8 | 10-12 | 12-15 | 15-20 |

| Power (kW) (Dual Motor) | 11/15 | 18.5/22 | 30/37 | 37/45 | 45/55 |

Our experts are on hand to help you with any questions you may have about fertilizer equipment.

The various raw materials of fertilizers go through the entire process of feeding, crushing, mixing, conveying, granulation, drying, cooling, screening, coating, and packaging.

For wet or sticky materials with a moisture content of up to 40%, choose a model with an anti-stick lining. This is especially useful for high-moisture materials like fertilizer (urea, ammonium phosphate) and clay.

The cage mill crusher is an excellent choice for crushing limestone. It features multiple layers of concentrically arranged steel cage bars. Material is repeatedly impacted and crushed through friction as it moves between these high-speed rotating bars. This makes it ideal for medium to low-hardness, brittle materials, producing a uniform particle size with minimal over-grinding.

Our lump breaker is perfectly suited for this. It features high wear-resistant alloy components and a heavy-duty welded frame, paired with hydraulic overload protection for superior impact resistance and anti-deformation. Its vibration-damping design reduces loss from vibration, ensuring stability and long life even in harsh working conditions. This crushing machine is highly tolerant of incoming material, capable of directly handling large blocks of 1-1.5 meters without pre-crushing, meeting the demands of large-scale production.