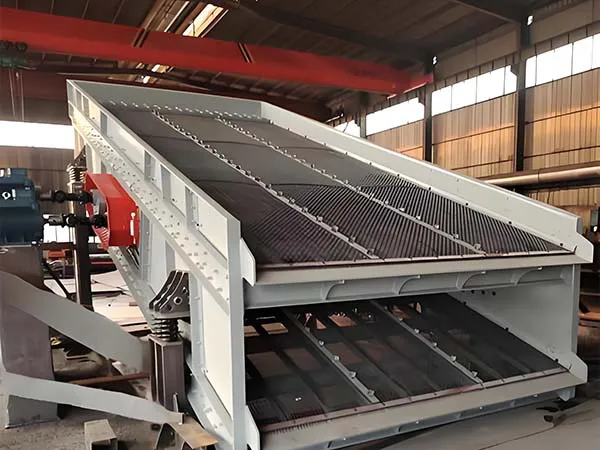

Vibrating flip-flow screen can be categorized as a linear, circular, or exciter-type vibrating screen. It is widely used in industries like mining, coal, chemicals, food, and building materials for the precise screening and grading of various granular and powdered materials. In the fertilizer industry, it is essential for sorting different-sized granules to ensure product quality and a smooth production process.

Continuous and rapid vibration spreads material evenly across the screen, effectively preventing particles from clumping and blocking the mesh. This enhances the flow rate and throughput of the screening process.

Screen meshes with different apertures can be changed as needed. Fine-tuning the amplitude and frequency ensures that the particle size of each batch is stable and within a controllable error range. The combination of an eccentric exciter and spring/rubber isolation mounts concentrates the vibration force within the screen box, which can quickly loosen wet, sticky materials while maintaining a continuous flow of dry powders to prevent mesh clogging.

| Model | Screening Area (m²) | Production Capacity (t/h) | Motor Power (kW) | Vibration Frequency (beats per minute) | Amplitude (mm) | Remarks |

| | 3 | 3-5 | 2×1.1 | 960 | 4-6 | Single-deck and double-deck screens are available for customer to choose |

| | 4.8 | 5-10 | 2×1.1 | 960 | 4-6 | |

| | 7 | 10-15 | 2×1.5 | 960 | 4-6 | |

| | 7.5 | 15-20 | 2×1.85 | 960 | 4-6 | |

| | 9.6 | 20-25 | 2×2.2 | 960 | 4-6 | |

| | 10 | 25-30 | 2×2.2 | 960 | 4-6 | |

| | 12 | 30-35 | 3×2 | 960 | 4-6 | |

| | 13.2 | 35-40 | 3×2 | 960 | 4-6 |

The screen body is made of Q235 steel, and the screen mesh is made of stainless steel.

Our experts are on hand to help you with any questions you may have about fertilizer equipment.

The various raw materials of fertilizers go through the entire process of feeding, crushing, mixing, conveying, granulation, drying, cooling, screening, coating, and packaging.

A vibrating flip-flow screen is the ideal choice when your screening requirements fall between those of a trommel screen and a vibrating sieve. It's suitable for materials that are not extremely fine or exceptionally large. Its hourly screening capacity is higher than a vibrating sieve but lower than a trommel screen.

The vibrating sieve is perfect for this. By adjusting the vibration parameters (amplitude, frequency) and selecting the right screen mesh, it can accurately separate materials by particle size. Its high-frequency vibration effectively prevents blockages and enhances both screening efficiency and precision.

The vibrating flip-flow screen is a great fit. Its continuous, rapid vibration spreads the material evenly across the screen, preventing clumping and blockages to ensure smooth, high-capacity screening. It's primarily used for the precise screening and grading of various granular and powdered materials. In the fertilizer industry, it's essential for sorting materials to maintain product quality and a smooth production process.