Fertilizers and Dry Bulk Materials

Belt conveyor is a versatile and continuous conveying device. Widely used in industries like mining, ports, power, and building materials, it efficiently transports lumpy, granular, and powdered materials (such as ore, coal, and sand) as well as packaged goods (like boxes and parcels). Its high-efficiency, low-damage design makes it a core piece of equipment for long-distance, high-volume material transfer.

Supports non-stop operation. Conveying capacity can be precisely matched to material properties and production needs by adjusting the belt speed and width.

Available with various belt materials (rubber, PVC, nylon, etc.) to suit high-temperature, humid, and corrosive environments, such as underground mining or food-grade applications.

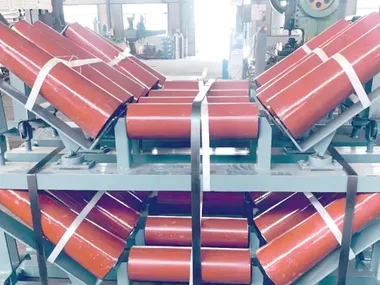

The synergy between the idler and roller sets ensures smooth belt operation, reducing the risk of shaking or wandering.

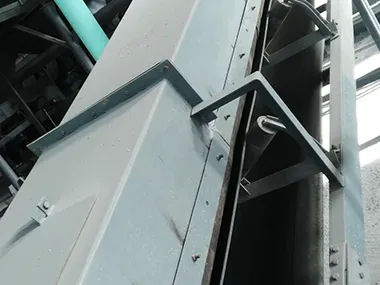

The bracket material is Q235 steel, and the belt is made of wear-resistant, acid- and alkali-resistant rubber.

| Conveying Capacity (t/h) | Belt Width (mm) | Power Range (kW) | Conveying Speed (m/s) | ||||||

| 0.8 | 1 | 1.25 | 1.6 | 2 | 2.5 | 3.15 | |||

| 500 | 1.5~30 | 78 | 97 | 122 | 156 | 191 | 232 | - | |

| 650 | 1.5~40 | 131 | 164 | 206 | 264 | 323 | 391 | - | |

| 800 | 2.2~75 | - | 278 | 348 | 445 | 546 | 661 | 824 | |

| 1000 | 3~100 | - | 435 | 544 | 696 | 853 | 1033 | 1233 | |

| 1200 | 4~185 | - | 655 | 819 | 1048 | 1284 | 1556 | 1858 | |

| 1400 | 4~185 | - | 891 | 1115 | 1427 | 2118 | 2118 | 2528 | |

| Conveying Capacity (t/h) | Belt Width (mm) | Power Range (kW) | Conveying Speed (m/s) | ||||||

| 4 | 0.8 | 1 | 1.25 | 1.6 | 2 | 2.5 | |||

| 500 | 1.5~30 | - | 41 | 52 | 66 | 84 | 103 | 125 | |

| 650 | 1.5~40 | - | 67 | 88 | 110 | 142 | 174 | 211 | |

| 800 | 2.2~75 | - | 118 | 147 | 184 | 230 | 289 | 350 | |

| 1000 | 3~100 | - | - | 230 | 288 | 368 | 451 | 546 | |

| 1200 | 4~185 | 2202 | - | 345 | 432 | 553 | 677 | 821 | |

| 1400 | 4~185 | 2996 | - | 469 | 588 | 753 | 922 | 1117 | |

Our experts are on hand to help you with any questions you may have about fertilizer equipment.

The various raw materials of fertilizers go through the entire process of feeding, crushing, mixing, conveying, granulation, drying, cooling, screening, coating, and packaging.

We recommend our scraper conveyor. It's an industrial device designed for continuous and enclosed transport of bulk materials. Ideal for horizontal or inclined conveyance of lumpy, granular, and powdered materials, it excels in harsh conditions with high temperatures, moisture, and dust. Its fully enclosed structure effectively prevents dust leakage, meeting all environmental regulations.

Our belt conveyor is perfect for continuous, non-stop operation. Its capacity can be precisely matched to your material's characteristics and production needs by adjusting the belt speed and width. We offer a variety of belt materials, including rubber, PVC, and nylon, to handle high-temperature, humid, and corrosive environments.

Our screw conveyor is specifically designed for the enclosed transport of powdered, granular, and small lumpy materials. Suitable for horizontal, inclined, or vertical conveyance, it's ideal for materials that are prone to dust, are toxic, flammable, or require mixing. By adjusting the rotation speed, you can precisely control the conveying volume, adapting to different production rhythms for fine-tuned material feeding.